Dark field optical observation of polymer powder bed fusion for process monitoring and control

July 2023·,,,,·

0 min read

Derek Black

Jacob Henderson

Philip Klocke

Landon Shumway

Nathan B. Crane

Abstract

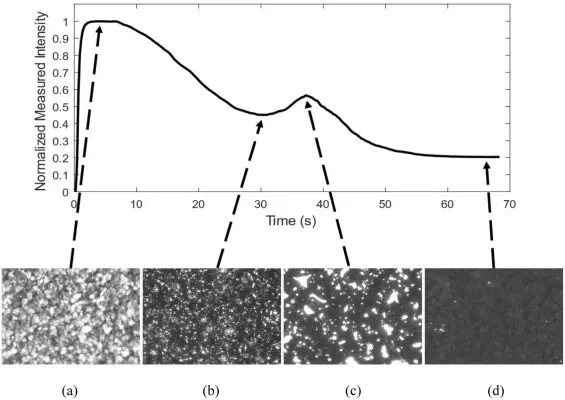

Polymer powder bed fusion (PBF/P) is one of the most promising additive manufacturing (AM) categories for producing end-use parts. However, many of the industries that would benefit the most from end-use AM parts are not able to use PBF/P due to a lack of quality assurance. The ability to predict part performance in small quantity production is essential for high-consequence applications. Many methods have been developed for monitoring defects and process variables in PBF/P but lack a clear connection to the resulting properties of the printed part, such as density and ultimate tensile strength (UTS). This paper presents a novel monitoring technique that uses visible-wavelength imaging to track melting progression during printing. In a dark-field orientation, the smoothening of the powder-bed and changes in reflectance due to melting produce a nonmonotonic intensity profile with identifiable features that are representative of different stages in the melting progression referred to as optical melting states (OMSs). This work shows that OMS strongly correlates to both density and UTS for polyamide 12 (PA12). Variation in density due to different print geometries and system variation was also highly correlated to OMS measurements. Density variation between parts with varying geometry was reduced by 68% with closed-loop control using OMS measurements compared to fixed-exposure time prints. Since the method is based on the geometric smoothing during viscous sintering, it can be used on materials with minimal prior knowledge of material properties as demonstrated by printing a thermoset polyurethane without providing any material-specific parameters to the exposure time control algorithm. The technique was demonstrated with Large Area Projection Sintering (LAPS) and could potentially be implemented with other PBF/P processes.

Type

Publication

Additive Manufacturing